Chapter Eight: Nose Job

Day 1

It took a few weeks to work out going back over to Camp Verde. There

was work, racing, etc. I finally went on Memorial Day weekend. Earl

Watts had a couple days off, so I flew over to Phoenix, and rode the

little shuttle bus. Actually, the way things worked out, I flew late,

stayed in a motel and went up the next morning. Earl picked me up and we

bought a few necessary items.

I managed to get very slippery wax all over the floor in the grocery

store. "Wet, slimy clean-up in aisle 10. Stupid blonde customer

went nuts and spilled it."

I'd already purchased a number of items, and Kevin at Quintus

Marine had contributed resin, catalyst, cloth and a recipe. We discussed

several things about our techniques and options, and by about 1pm, we

were doing real work.

First we turned the body 180 degrees from where Earl had it sitting.

He'd come up with a platform affair, using two pieces of galvanized

roofing, which I must admit did not please me when I saw it but it

worked very well for what we needed. I appreciate his efforts and the

price was right.

The next thing we did was to erect a tent over the project. This was

a lifesaver as the heat was pretty intense that weekend. We then drilled

into the fiberglass rocker panels and bolted the body to the platform to

maintain as much of the size, shape and integrity of the 33-year-old

fiberglass as possible. |

Earl Watts watches Kevin remove paint with a "DA" and

100grit. |

We went about many tasks, then measured and made a line across the

place to be cut.

My original intent was to use wax on the body, pour resin and cloth

on top and make a female mold to form the actual piece we'd use to

fill the six-inch gap. It could have worked, and we messed with some wax

and glass. It was mutually decided that we could shortcut that

procedure. |

Earl

and Kevin measure the nose for proper placement of cut.

|

Earl had a roll of roof "flashing" -- thin galvanized steel

sheathing from some previous project. We cut a couple short pieces and

tested it to see if we could form it to the body contours. It worked

better than we imagined.

So, out came the pneumatic cutting tool and Earl began carving the

nose off the Nova. I did my part too but just couldn't bear to make

that first cut. You understand. |

I couldn't do it so Earl made the first cut. |

Later, with the nose severed, we discovered a fairly major problem.

It seems that every place the body builder had installed strengtheners

-- stringers -- and the surface had been breached, the foam had rotted.

We chose to cut and grind much of it out. |

We decided to grind out as much of the rotten foam as possible and

glass over the

section. Earl goes after some of it on the removed nose

section. |

Rotten foam was found in many places. We got rid of most of it. With

that accomplished, at least right where we were going to work, we set

the nose up approximately where we thought it looked right. Then we

measured carefully and bolted it solidly to the jig. The remaining gap

was what we needed to fill. |

|

|

Then came the sheathing, which we cut, roughly shaped and pop-riveted

into place. We also added a few extra wooden place-holders of various

sizes to hold the body in position.

Then came the sheathing, which we cut, roughly shaped and pop-riveted

into place. We also added a few extra wooden place-holders of various

sizes to hold the body in position. |

At

the end of that first day, we had accomplished a great deal and we

actually had a much better idea of what the body would look like. At

the end of that first day, we had accomplished a great deal and we

actually had a much better idea of what the body would look like.

We were concerned about glassing itself, and whether the fiberglass

would stick to the sheathing or the galvanized jig floor. But we cleaned

ourselves up, ate some, watched a little TV and slept. |

|

| Day 2

Early the next morning, we duplicated the gap-filling sheathing on he

right side, cut a few pieces of cloth and Earl mixed up the first batch

of resin.

Please note that when we did the sheathing "mold" on the right

side, we got out

every tool Earl Watts owns! |

|

|

|

I

could tell you that we used all kinds of tricks to apply the fiberglass

but in reality it was a matter of dabbing resin and sticking fiberglass

in the gap until there was no gap. We used gloves. We used sticks. We

used brushes. We used fingers. It was messy. I

could tell you that we used all kinds of tricks to apply the fiberglass

but in reality it was a matter of dabbing resin and sticking fiberglass

in the gap until there was no gap. We used gloves. We used sticks. We

used brushes. We used fingers. It was messy. |

What

every good fiberglass guy wears this season!

|

When the glasswork began, we learned as we went, quickly discovering

that it almost didn't matter what we did, as long as we kept ahead of

when the resin "kicked."

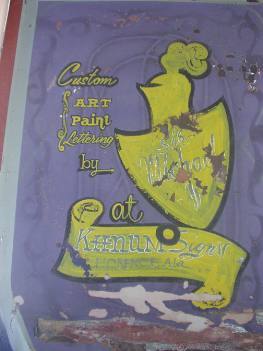

While waiting for each layer of glasswork to setup, we did other

tasks, mostly removing the 30-year-old paint. Whoever did it had ideas

not mine. My theory is that Mr. Duckett had a friend that sponsored the

paint, but had no say in what went on. The artist (see shield) added

dozens of elements that were to portray all of his painting and

lettering abilities. There were ships, ghostly women, a hookah, pin

striping and a variety of fonts, colors and flavors that may or may not

have fit together at all. But, it was the early 70s after all. |

I

used some chemical stripper on the top and trunk. Kevin and Earl used a

DA with fairly aggressive grit on the sides. We rarely sat around and

did nothing. There is still more to do. I

used some chemical stripper on the top and trunk. Kevin and Earl used a

DA with fairly aggressive grit on the sides. We rarely sat around and

did nothing. There is still more to do.

We stayed at it most of the day and by quittiną time, both sides had

plenty of layers.

After clean up, we discussed another ingredient at some length. There

was more of the ugly work of grinding and cutting out the rotted glass

and foam and I wanted to get the dust away from the Watts' two horses.

And, too work the top of the body the back of the hood and cowl area --

properly, we needed to invert the Nova. |

|

| Day 3

Our hearts pounded as if there were drums rolling. It was the moment

of truth. Would our work hold together? Would the glass come loose from

the deck of our table jig or from the sheathing?

Earl, a master of jury-rigging, came up with a simple plan to hold

the body upside down. A few pieces of iron, a couple concrete blocks,

some twine, and the back of the old International COE made for a superb,

stable resting place.

We cut the body loose far easier than we suspected -- and muscled it

over to its new place on the other side of the garage. |

Earl grimaces while trying to carry the body and walk backwards. Check out the jig

he quickly assembled to hold up the nose! When we carried

the

body, even flipping it over, we realized how strong our little

"repair" already was. |

|

We were quite astonished as to just how strong our work was and we were

only done with the sides! As soon as we set it down, a couple of the

Watts dogs scampered inside the body to inspect our work. They seemed to

approve. As can be seen in the pictures, we formed the piece of

sheathing as best we could, including the center-of-the-hood peak.

I ground out some more rot and we cleaned that up as best we could. |

|

Then

we chose some cloth and started putting down layer after layer of glass.

It was much easier sticking the pieces in horizontally than it had been

vertically. Funny how a little thing like gravity helps so much. Then

we chose some cloth and started putting down layer after layer of glass.

It was much easier sticking the pieces in horizontally than it had been

vertically. Funny how a little thing like gravity helps so much. |

Kevin

worked hard on removing paint. Note by the amount of dust in the air

that our decision to move the project away from the horses was a good

one. Kevin

worked hard on removing paint. Note by the amount of dust in the air

that our decision to move the project away from the horses was a good

one. |

The help I received on this project was invaluable. Earl just about

wore

out himself

and his tools.

|

After a few hours, and a lot of resin and cloth, we called it good

enough and cleaned up everything.

We tore down the jig fixture we'd used the first two days and

returned the roofing panels to their rightful spot. We then cleaned

ourselves up and headed for a Mexican dinner. That place was closed

though, so Kevin, Earl, Laurie and I had Chinese. After that, we filled

the truck with fuel, and back at the house, hooked up the little trailer

that usually hauls Laurie's dragster and relaxed. |

|

| Day 4

We grabbed the body, threw it on the trailer, tied it down and were

eating at Cracker Barrel in east Flagstaff by about 8:30am. The drive

from the Watts' estate to Winslow is about two hours with

"Flag" almost directly in the middle.

Then, I requested to stop at an old landmark, the old "Twin

Arrows" gas station and souvenir store. I don't know the history

of the place other than it still exists. I took a few pictures, then we

moved on. |

The newly stretched Nova gets a respite on the way to Winslow.

Twin Arrows was a major tourist attraction on Route 66 and the remains are

still

just off I-40 east of Flagstaff, Arizona.

|

We soon passed Two Guns, so I guess the two places must have been

created somewhat tongue-in-cheek to bookend some sort of happening in

the desert of western Arizona.

When we got to Ron's Racing, Chris Stinson met us and was quite

impressed with the new length when we dropped the body over the chassis.

Actually, he complained that we'd added six inches when he really

wanted five. Oh well. |

Earl

Watts and Chris Stinson quickly removed the galvanized sheathing. We

decided to leave it on during the transport phase for the added strength

but it was truly unnecessary.

Earl and Chris jumped to removing the tin we'd added for the mold.

We decided to leave it on while loading and transporting the body for

added strength and to make sure the resin had fully hardened. It was

unnecessary. And, we quickly discovered that the galvanized steel had

been a perfect choice the glass did not stick to it and the remaining

surface was fairly nice and smooth. |

I

tried to duplicate an old picture of Don Hardy I saw where he is

indicating how much he'd just added to the nose of a 69 Camaro body. I

had Earl Watts pose. You get the idea. I

tried to duplicate an old picture of Don Hardy I saw where he is

indicating how much he'd just added to the nose of a 69 Camaro body. I

had Earl Watts pose. You get the idea.

One that had concerned me was that by adding six inches to a Nova it

would appear nose heavy. But, the look is great. It'll be a perfect FC

body. |

I

did get to climb in and try out the chassis fit, with Laurie shooting a

few pictures. With body off and on, I feel pretty comfortable in the

car. As I said before, I need to cut out a few snacks. I

did get to climb in and try out the chassis fit, with Laurie shooting a

few pictures. With body off and on, I feel pretty comfortable in the

car. As I said before, I need to cut out a few snacks. |

I did get a chance to try out the car and feel good about

the feel. Chris and I conferred about the placement of several minor

things such as brakes, throttle, chute release, etc. |

|

The new look and feel seems right to me. What do you think?

For the most part, we all agreed that the body stretch was a positive

accomplishment and things seemed to fall into place. Keep in mind that

the fitting of the body would need a little more thought by Chris. After

a couple hours of conversation and note taking, we piled back in the

truck and headed back for Camp Verde. I packed quickly, they dropped me

at the shuttle stop and I was soon headed back for Phoenix, Southwest

Airlines, Burbank and SoCal. It had been a long, hot productive weekend. |

|